Capabilities

1. R&D

The company's core team has more than 20 years of rich experience and professional knowledge, continuous research and development, improvement of film labeling and injection molding technology and process, can solve a variety of injection molding, labeling problems, and won a number of patent certification

Production Process

2.Materials

PP

High temperature resistant cooking (121 ℃, 45Min, no peculiar smell)

Resistant to low temperature freezing (-20 ℃)

PE

Can be pasteurized (85 ℃,30Min)

Resistant to low temperature freezing (-20 ℃)

Industrial resin

1. strong plasticity: resin material modeling force is very strong, can produce a variety of shapes, wide range of applications. Can be made such as resin crafts, resin waist line and so on.

2. strong decorative: its material performance is exquisite, with resin material production of product texture is excellent, can be in accordance with the requirements of the design style, color or size and so on.

3. Durable: resin material surface finish high, and its products good flexibility, corrosion resistance, high and low temperature resistance, anti-aging, long service life.

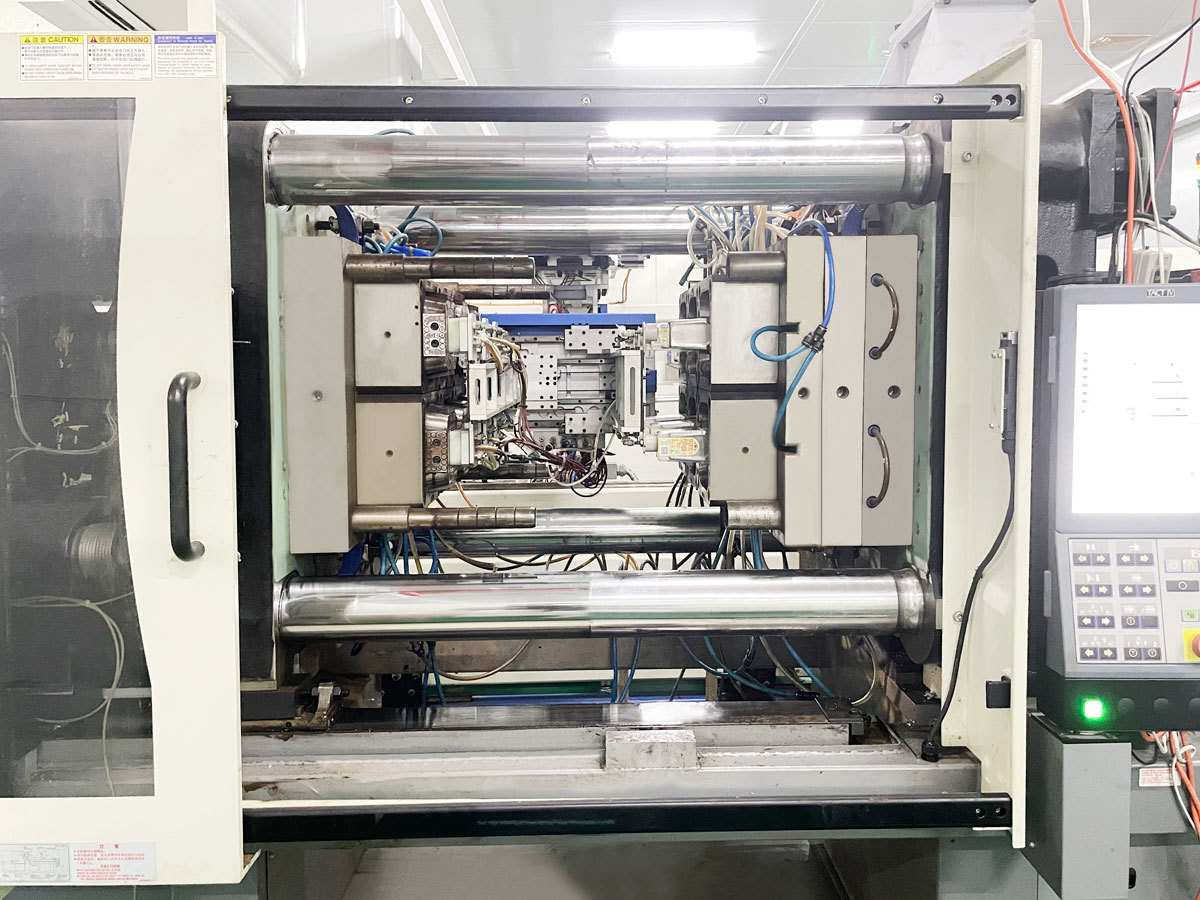

3.Mold Making

Equipped with various specifications of 1-out-of -8-hole high-speed in-mold sticking mold and 1-out-of -64-hole straw mold, with an 8-second production cycle, each set produces more than 80000 products per day.

4.Production

Automatic in-mold labeling production

5.Quality Assurance

Raw material control

Strict selection of quality suppliers from the beginning of the selection of suppliers. For example, Sinopec and other well-known brands

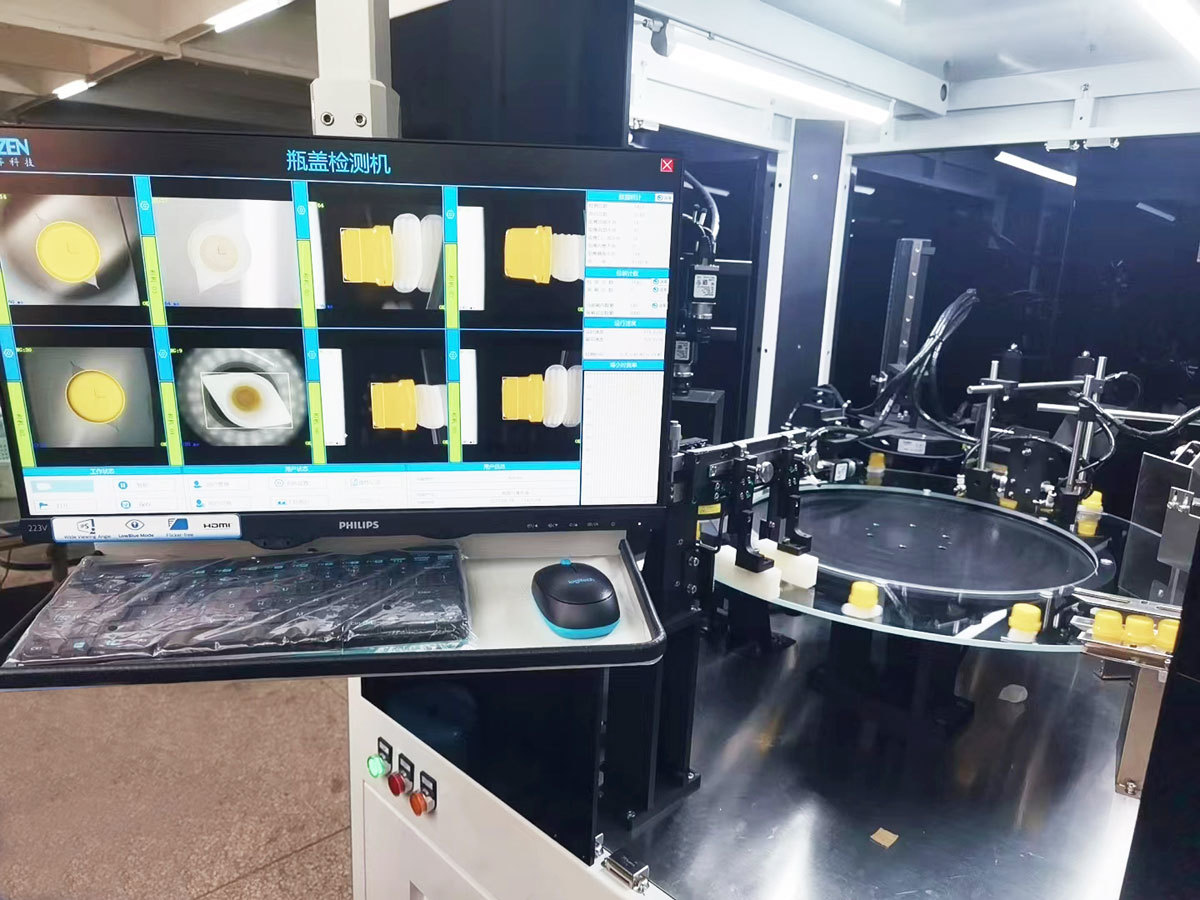

Production inspection

1) Air tightness test;

2) Twist-off force inspection;

3) Material property aging test;

4) Fading detection

Finished product inspection

In strict accordance with the international sampling standards of 105E. And from time to time by a third-party laboratory for product testing.

Quality Certificate

The company has passed ISO9001 international quality management system certification, SGS certification, FDA certification, BRC certificate, etc. At this stage, we can provide customers with up to thousands of functional nozzles and low-cost and efficient packaging products. Our products are widely used in bio-pharmaceutical, daily chemical products, food and beverage, automotive supplies and other applications.

Guangdong Caixin Plastic Co., Ltd.

Fax: 86-754-83143323

Address:No.128, Chaoshan road, Jinping District, Shantou, Guangdong Province, China

Copyright©Guangdong Caixin Plastic Co., Ltd. SEO Powerde by:www.300.cn Privacy Policy