Unlocking the Benefits of Best IML Packaging for Your Products

2025-03-10 11:40

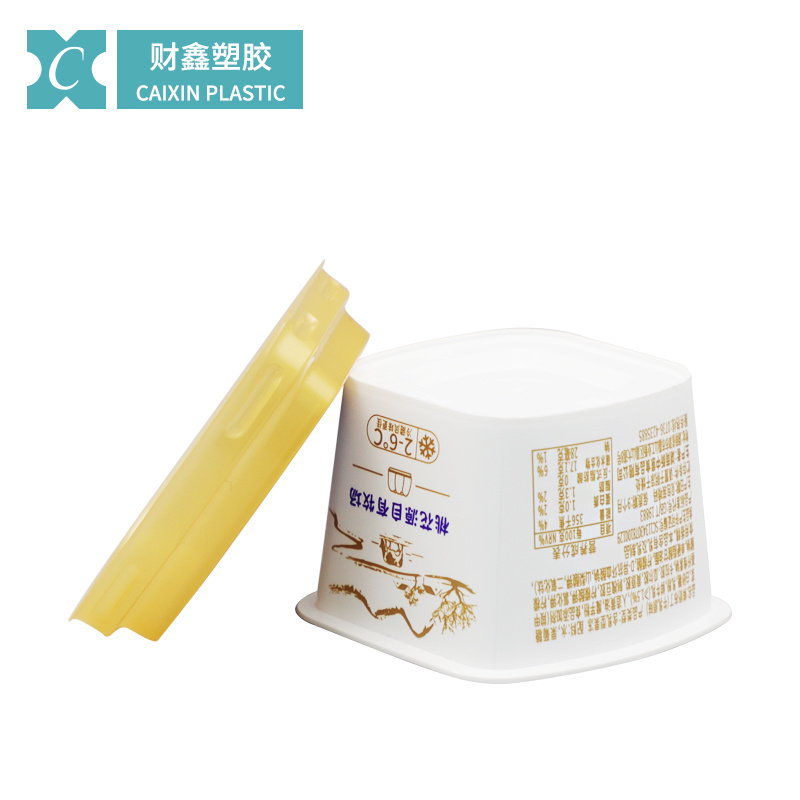

In a world where product presentation plays a crucial role in consumer decisions, In-Mold Labeling (IML) packaging has emerged as a game changer. This innovative packaging technology not only enhances the aesthetic appeal of products but also boosts functionality and sustainability. In this article, we will explore how IML packaging can unlock numerous benefits for your products, making them stand out in a saturated market.

What is In-Mold Labeling (IML)?

In-Mold Labeling (IML) is a process where a label is placed in the mold before the plastic is injected. During the injection molding process, the label fuses with the plastic, creating a durable and visually appealing product. This technique eliminates the need for additional adhesives or labels, making it an efficient and cost-effective solution for packaging.

Key Benefits of IML Packaging

IML packaging offers a plethora of advantages that can significantly enhance your product's marketability. Below, we delve into the most compelling benefits.

Aesthetic Appeal and Branding

One of the most significant advantages of IML packaging is its ability to provide high-quality graphic outputs. With IML, brands can achieve vibrant colors, intricate designs, and complete surface coverage, making products visually striking. This eye-catching appeal not only attracts customers but also fosters brand recognition. A well-designed IML package can effectively convey your brand's identity, values, and messaging, enhancing customer loyalty.

Durability and Protection

IML packaging is known for its exceptional durability. The process of integrating the label directly into the mold provides resistance to scratching, fading, and moisture. This contributes to greater product shelf life, ensuring that your items remain visually appealing from production to consumption. Additionally, IML packaging can withstand various environmental conditions, offering protection during transportation and storage.

Sustainability and Eco-Friendliness

As consumers become more environmentally conscious, sustainable packaging solutions are gaining importance. IML packaging is typically made from recyclable materials, contributing to a reduced carbon footprint. Furthermore, the process itself minimizes waste by integrating the label into the final product, unlike traditional labeling methods that often rely on adhesives that can be harmful to the environment. Adopting IML packaging demonstrates your brand’s commitment to sustainability, appealing to eco-conscious customers and enhancing your corporate social responsibility profile.

Cost-Efficiency and Production Speed

The efficiency of IML packaging can lead to considerable cost savings. By combining labeling and packaging into a single process, manufacturers can reduce labor costs and production time. This streamlining of operations not only boosts productivity but also allows for quicker response times to market demands. As a result, businesses can achieve higher outputs at lower costs, making IML a financially viable option for a wide range of products.

Applications of IML Packaging

The versatility of IML packaging makes it suitable for various industries, including food and beverage, cosmetics, household products, and more. Here are some common applications:

Food and Beverage Industry

In the food and beverage sector, IML packaging ensures safety and extends shelf life. Products such as yogurt containers, sauces, and ready-to-eat meals benefit from the durability and attractive appearance of IML packaging.

Cosmetics and Personal Care

IML packaging is perfect for cosmetic products like creams, lotions, and makeup containers. Its ability to create intricate designs and maintain product integrity makes it a favorite among brands seeking to make an impact in a competitive market.

Household Products

Household items, including cleaners and detergents, also utilize IML packaging. The packaging not only provides essential product information but also enhances the overall brand image through striking designs.

IML vs. Traditional Labeling Methods

When comparing IML packaging to traditional labeling methods, several key differences stand out:

Adhesive vs. Integration

Traditional labeling often relies on adhesives, which can result in peeling or fading over time. In contrast, IML packaging integrates the label into the product itself, ensuring longevity and durability.

Production Time and Costs

Traditional methods may require additional steps in the production process, leading to increased labor costs and longer lead times. IML packaging combines label application and product molding, providing a streamlined production process.

Visual Quality

IML packaging offers superior visual quality, with vibrant colors and intricate designs that are often unattainable with traditional label printing techniques.

Challenges in Implementing IML Packaging

While IML packaging presents numerous benefits, there are challenges to consider:

Initial Investment and Equipment

The transition to IML packaging may require significant investment in specialized equipment. Businesses must weigh these costs against the long-term benefits of the technology.

Complexity of Design

Creating effective IML designs requires a skilled approach to ensure that the artwork aligns well with the molding process. Companies need to collaborate closely with designers to achieve optimal results.

The Future of IML Packaging in the Industry

As technology advances, the future of IML packaging looks promising. Innovations in materials, processes, and design capabilities will likely enhance the effectiveness of IML packaging solutions. Furthermore, as sustainability becomes a priority, IML packaging can evolve to meet consumer demands for eco-friendly options.

In summary, In-Mold Labeling (IML) packaging is a revolutionary approach that offers a myriad of benefits for businesses looking to enhance their product offerings. From improved aesthetics to increased durability and sustainability, IML packaging can significantly impact brand recognition and consumer satisfaction. As the market continues to evolve, embracing IML technology can position your products for success in an increasingly competitive landscape. By understanding and leveraging the advantages of IML packaging, companies can unlock new opportunities for growth and innovation.

recommend News

Guangdong Caixin Plastic Co., Ltd.

Fax: 86-754-83143323

Address:No.128, Chaoshan road, Jinping District, Shantou, Guangdong Province, China

Copyright©Guangdong Caixin Plastic Co., Ltd. SEO Powerde by:www.300.cn Privacy Policy