The Versatility of Famous Plastic Flip-Top Lids in Modern Packaging

2025-05-03 11:20

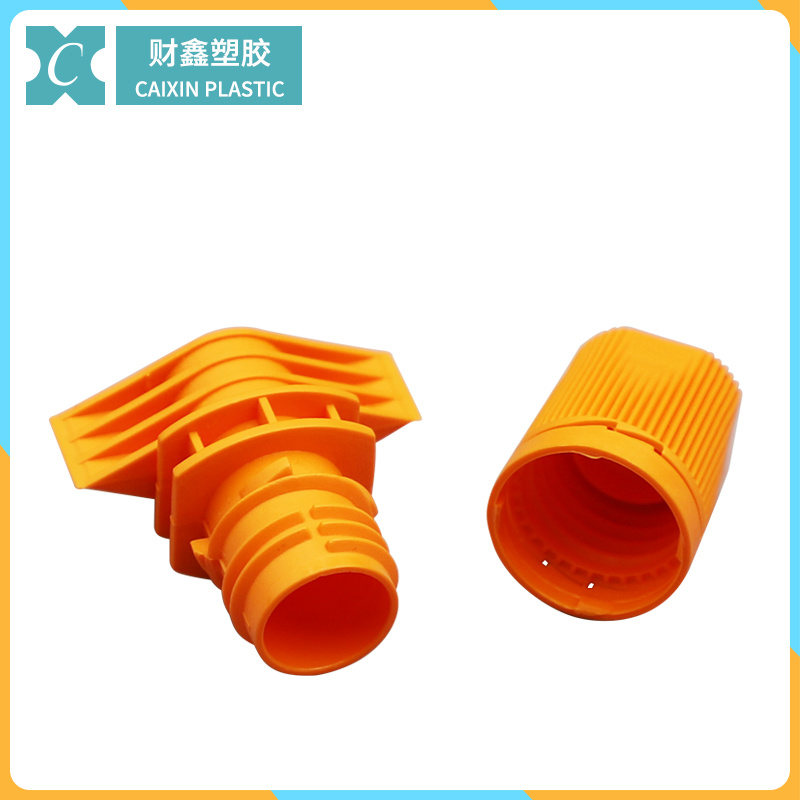

In the realm of packaging, the **plastic flip-top lid** has emerged as a practical and popular choice for a wide array of products. From condiments and personal care items to pharmaceuticals and household cleaners, these lids provide an effective solution that combines convenience with durability. **Flip-top lids** cater to modern consumer needs by offering ease of use and a secure seal, which is crucial for maintaining product freshness and safety.

A Brief History of Flip-Top Lids

The concept of using lids for containers is ancient, but the **flip-top lid** as we know it has undergone significant evolution. Originally designed for **glass bottles**, these lids transitioned to plastic as manufacturing techniques improved. By the late 20th century, flip-top lids became ubiquitous in consumer packaging, especially with the rise of convenience culture. The innovation of snap-on and flip-top designs revolutionized the way products are packaged, ensuring that they are both user-friendly and efficient.

Design Features of Plastic Flip-Top Lids

The design of **plastic flip-top lids** is an intriguing mix of functionality and aesthetic appeal. Here are some key features:

Ergonomic Shapes

Many flip-top lids are designed with ergonomic considerations in mind, making them easy to open with one hand. This design is particularly useful for consumers juggling multiple tasks.

Material Versatility

Most flip-top lids are made from high-quality, recyclable plastic, which not only ensures durability but also contributes to sustainability efforts. This material choice allows for customization in colors and finishes.

Sealing Mechanisms

The sealing mechanisms of flip-top lids are engineered to provide an airtight seal that prevents spills and contamination. This feature is crucial for products like sauces and lotions, where maintaining the integrity of the contents is essential.

Customization Options

Brands can customize flip-top lids with their logos, colors, and designs, enhancing brand recognition while ensuring the packaging aligns with aesthetic values.

Benefits of Using Flip-Top Lids in Packaging

Utilizing **plastic flip-top lids** in packaging comes with a multitude of advantages:

Convenience for Consumers

Flip-top lids allow for easy and quick access to contents, particularly for products used regularly, such as shampoo or ketchup. Consumers appreciate the ability to pour or squeeze without removing the lid completely.

Enhanced Product Freshness

The secure closure provided by flip-top lids helps retain the quality of the product inside. This is especially important for food items, where exposure to air can lead to spoilage.

Cost-Effectiveness

Manufacturing plastic lids is often more affordable than metal or glass alternatives, providing a cost-effective solution for packaging needs. This can lead to reduced overall packaging costs for companies.

Improved Shelf Life

By preventing contamination and exposure to air, flip-top lids can help extend the shelf life of many products. This is crucial in industries like food and pharmaceuticals, where expiration dates are a concern.

Applications Across Various Industries

The versatility of plastic flip-top lids makes them suitable for a wide range of applications:

Food and Beverage

In the food industry, **flip-top lids** are common on condiment bottles, sauces, and ready-to-drink beverages. They facilitate easy pouring and minimize spills, enhancing the user experience.

Personal Care Products

For personal care items like lotions, gels, and shampoos, flip-top lids are favored for their ability to protect contents while remaining accessible for daily use.

Household Cleaners

Plastic flip-top lids are prevalent in household cleaning products. Their secure fit ensures that harmful chemicals remain contained, making them safer for households.

Pharmaceuticals

In the pharmaceutical industry, flip-top lids provide a secure and tamper-evident closure that is essential for both safety and regulatory compliance.

Sustainability and Environmental Impact

With growing awareness of environmental issues, the packaging industry is under pressure to adopt more sustainable practices. **Plastic flip-top lids**, particularly when made from recyclable materials, can contribute to these efforts.

Recyclable Materials

Many manufacturers are now producing flip-top lids using materials that are 100% recyclable. This helps reduce waste and encourages responsible consumer behavior.

Reduced Carbon Footprint

The lightweight nature of plastic flip-top lids means lower transportation costs and reduced carbon emissions compared to heavier packaging options.

Innovative Materials

Some companies are exploring biodegradable plastics for flip-top lids, which can further minimize environmental impact while still providing the necessary functionality.

Future Trends in Flip-Top Lid Design

As technology and consumer demands evolve, the design of flip-top lids will continue to change. Notable trends include:

Smart Packaging

The integration of technology into packaging is on the rise. Future flip-top lids may feature QR codes or NFC chips that provide consumers with additional product information or promotions.

Enhanced Customization

As competition grows, brands will likely invest in unique flip-top lid designs to differentiate their products. Custom colors, shapes, and user-friendly features will become standard.

Focus on Sustainability

The push for eco-friendly packaging will intensify, leading to more innovations in materials and designs that prioritize sustainability without sacrificing functionality.

Frequently Asked Questions

1. What are the primary materials used for plastic flip-top lids?

Flip-top lids are typically made from high-density polyethylene (HDPE) or polypropylene (PP), both of which are durable and recyclable.

2. Are plastic flip-top lids safe for food contact?

Yes, plastic flip-top lids manufactured for food products are designed to be food-safe and comply with regulatory standards for food contact materials.

3. Can flip-top lids be reused?

While flip-top lids are typically designed for single-use products, consumers may choose to reuse them for storage or crafts, provided they are cleaned properly.

4. How do flip-top lids compare to screw-on lids?

Flip-top lids offer more convenience and ease of use as they can be opened with one hand, while screw-on lids may provide a more airtight seal.

5. What innovations are expected in flip-top lid design?

Future innovations may include smart technology integration, enhanced customization options, and a stronger focus on sustainable materials that are biodegradable or made from recycled plastics.

Conclusion: The Future of Packaging with Flip-Top Lids

In conclusion, **plastic flip-top lids** have proven to be a versatile and indispensable component of modern packaging. With their wide-ranging applications, user-friendly designs, and sustainability potential, they are well-positioned to meet the evolving demands of consumers and industries alike. As we look to the future, innovations in design and materials will likely enhance their functionality, ensuring that plastic flip-top lids remain at the forefront of packaging solutions. Embracing these advancements will allow brands to not only improve their product offerings but also contribute positively to environmental sustainability.

recommend News

Guangdong Caixin Plastic Co., Ltd.

Fax: 86-754-83143323

Address:No.128, Chaoshan road, Jinping District, Shantou, Guangdong Province, China

Copyright©Guangdong Caixin Plastic Co., Ltd. SEO Powerde by:www.300.cn Privacy Policy