The Future of Fancy Plastic Nozzles: Trends and Innovations Shaping the Industry

2025-05-01 13:00

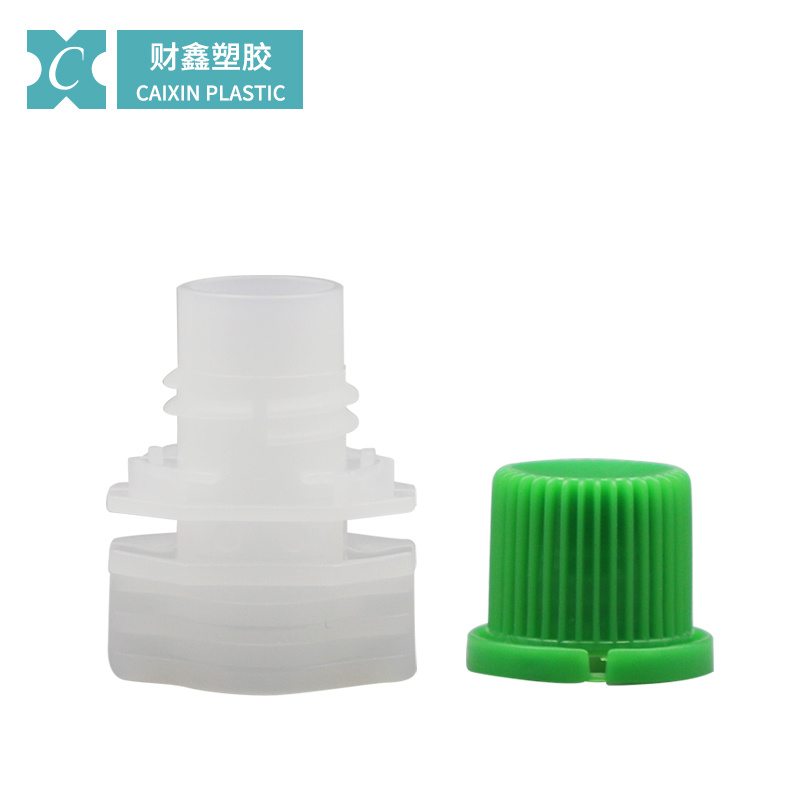

Fancy plastic nozzles play a crucial role in a variety of industries, from manufacturing to consumer goods. These intricate components are not just functional; they are becoming increasingly sophisticated and specialized to meet the demands of modern applications. As technology advances and consumer preferences shift, the future of fancy plastic nozzles promises to be dynamic and innovative.

Market Overview of Plastic Nozzles

The global market for plastic nozzles is expanding, driven by the rising demand for lightweight and durable materials. In recent years, industries such as automotive, food and beverage, and personal care have witnessed a growing need for advanced plastic nozzles that enhance product efficiency and performance. The increasing use of automation and robotics in manufacturing processes is further propelling this market's growth.

Key Industry Players

Major players in the fancy plastic nozzle market include established manufacturers as well as startups focusing on niche applications. These companies are investing heavily in research and development to create innovative solutions that cater to specific industry needs.

Market Trends

Emerging trends in the market include a shift towards customization and the integration of smart technologies into nozzle designs. This evolution is driven by the need for tailored solutions that can improve user experience and operational efficiency.

Trends in Design and Functionality

The design of fancy plastic nozzles is evolving to incorporate more complex geometries and functionalities. This shift is not merely aesthetic; it serves practical purposes and enhances performance.

Ergonomic Designs

Ergonomics is becoming a significant focus in the design of plastic nozzles. Manufacturers are keen on creating nozzles that are comfortable to use while ensuring ease of operation, especially in consumer-facing products. Features such as textured grips and adjustable spray patterns are gaining popularity.

Multi-Functionality

Consumers and industries alike are seeking multi-functional nozzles that can perform various tasks. From adjustable spray widths to interchangeable heads, the demand for versatility is influencing design trends in the industry.

The Rise of Sustainable Materials

Sustainability is a pivotal concern in today's manufacturing landscape. The push for eco-friendly products has led to the exploration of sustainable materials in the production of fancy plastic nozzles.

Biodegradable Plastics

Biodegradable plastics are gaining traction as manufacturers aim to reduce their environmental footprint. These materials offer similar performance qualities as traditional plastics but decompose more efficiently, contributing to a circular economy.

Recycled Plastics

Utilizing recycled plastics is another trend that is reshaping the industry. By incorporating recycled materials into their products, manufacturers can reduce waste and promote sustainability while maintaining the quality and functionality of their nozzles.

Advanced Manufacturing Techniques

The manufacturing landscape for fancy plastic nozzles is transforming, thanks to the adoption of advanced techniques such as 3D printing and injection molding.

3D Printing Innovations

3D printing technology allows for rapid prototyping and customization of plastic nozzles. This technique enables manufacturers to create complex designs that were previously unattainable, reducing time-to-market and production costs.

Precision Injection Molding

Precision injection molding techniques are being refined to enhance consistency and quality in nozzle production. This method allows for tightly controlled dimensions and improved surface finishes, which are essential for high-performance applications.

Applications of Fancy Plastic Nozzles

Fancy plastic nozzles find applications across various sectors, underscoring their versatility and functionality.

Automotive Industry

In the automotive sector, plastic nozzles are essential for fuel injection systems and various fluid dispensing applications. Their lightweight properties contribute to overall vehicle efficiency and performance.

Food and Beverage

In the food and beverage industry, specialized nozzles are crucial for packaging and dispensing products. Innovations in design ensure hygiene and precision in dispensing, meeting stringent regulatory requirements.

Personal Care Products

The personal care industry increasingly relies on fancy plastic nozzles for packaging lotions, sprays, and other products. The aesthetic appeal and functionality of these nozzles enhance consumer experience and product usability.

Future Outlook for Plastic Nozzle Innovations

The future of fancy plastic nozzles is bright, with numerous innovations on the horizon. As industries evolve, manufacturers must stay ahead of the curve by investing in research and adapting to new technologies.

Integration of Smart Technologies

The integration of smart technologies, such as IoT (Internet of Things) capabilities, is expected to revolutionize the functionality of plastic nozzles. Smart nozzles equipped with sensors can monitor performance, providing valuable data for optimization and maintenance.

Enhanced Customization

As consumer preferences become more specific, the demand for customized nozzles will rise. Manufacturers will need to develop solutions that cater to individual customer needs, enhancing the overall user experience.

Challenges Facing the Fancy Plastic Nozzle Industry

While the future looks promising, there are challenges that the fancy plastic nozzle industry must address.

Regulatory Compliance

With increasing environmental regulations, manufacturers face pressure to ensure that their products meet stringent standards. Navigating these regulations while maintaining quality and performance can be challenging.

Competition and Pricing Pressures

The market for plastic nozzles is becoming increasingly competitive, driving prices down. Manufacturers must find ways to differentiate their products without compromising on quality or profitability.

Conclusion

The future of fancy plastic nozzles is marked by innovation, sustainability, and advanced manufacturing techniques. As industries continue to evolve, these nozzles will play an integral role in enhancing product performance and user experience. By embracing emerging trends and addressing challenges, manufacturers can position themselves for success in this dynamic market.

FAQs

1. What are fancy plastic nozzles used for?

Fancy plastic nozzles are used in a variety of applications, including automotive, food and beverage packaging, and personal care products, enhancing functionality and user experience.

2. How are sustainable materials impacting the plastic nozzle industry?

Sustainable materials, such as biodegradable and recycled plastics, are becoming increasingly popular, allowing manufacturers to reduce their environmental footprint while meeting market demands.

3. What advanced manufacturing techniques are used in producing plastic nozzles?

Advanced techniques such as 3D printing and precision injection molding are used to create high-quality, precise nozzles tailored to specific applications.

4. What are the future trends in plastic nozzle design?

Future trends include ergonomic designs, multi-functionality, and the integration of smart technologies, catering to the evolving needs of consumers and industries.

5. What challenges is the plastic nozzle industry facing?

Challenges include navigating regulatory compliance, managing competition and pricing pressures, and adapting to the shifting demands of the market.

recommend News

Guangdong Caixin Plastic Co., Ltd.

Fax: 86-754-83143323

Address:No.128, Chaoshan road, Jinping District, Shantou, Guangdong Province, China

Copyright©Guangdong Caixin Plastic Co., Ltd. SEO Powerde by:www.300.cn Privacy Policy